When it comes to taking care of preventative maintenance, automation is your friend. In fact, the more automation that you are able to implement into your team’s workflow, the easier it is for them to get the work done.

Here are a few ways that preventative maintenance automation as well as automation in general is helpful when running a maintenance department.

Accuracy

Instead of fussing over spreadsheets or taking notes that may get lost or misinterpreted, using CMMS (Computerized Maintenance Management Software) ensures that everything is done with accuracy. Instead of writing down a hurried response on a Post-It note, you can easily add the work order from the simple to use Mobile App, assign it and it is automatically sent to the employee to take care of or re-assigned if it needs to be escalated.

Better Readings

Preventative maintenance is something that needs to be done with a regulated approach. With CMMS and an automated formulation, you are able to create a PM plan that is based on your facilities individual requirements. For example, you are able to adjust any PM to meet specifie changes to a regulated or audited inspecton. When doing standard checks, such as; air conditioning filters or checking a certain piece of machinery – or even oiling that piece of machinery, it can the guesswork out of when or what needs to be done.

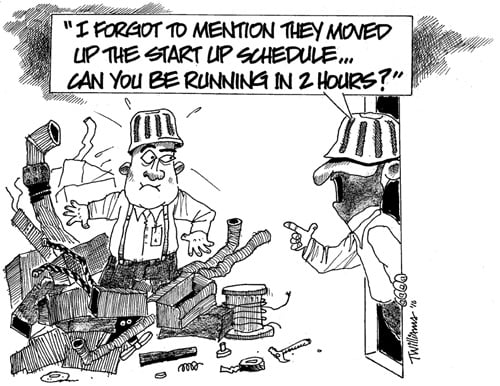

Workload Optimization

With automation you are able to optimize your workload. This is more easily done when basing it on employee availability and work requirements. You are better able to look at how many hours are needed for the work week and how much help you have to implement the tasks that need to be done – not just with preventative maintenance but work tasks and emergencies as well.

Read More: Avoid Simple Automation Mistakes

CMMS helps simplify your entire maintenance department workflow and create an environment that is easier to handle. It allows you peace of mind that with the touch of a button, you have all of the reports you need, can schedule work tasks, and preventative maintenance is handled and standardized and timely manner.