You may have heard the phrase condition-based maintenance but if you are not really familiar with what it is – here is a little bit about it and what you need to know to help your facility run more efficiently.

From Fit Bits to HVAC units that monitor humidity levels – these are just a couple examples of condition-based maintenance products.

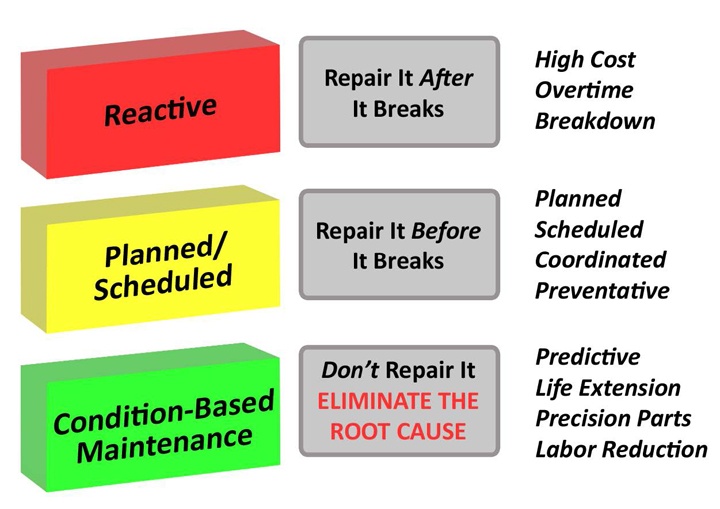

Condition-Based Maintenance

Condition-based maintenance is where maintenance is conducted on a piece of equipment once it reaches a level of disruption. It works is with sensors that communicate and let the maintenance manager know if the equipment is working properly in real time. These sensors communicate the information needed and then the data is available to be analyzed by a maintenance facility manager once it is retrieved from a CMMS (Computerized Maintenance Management Software) program.

In order for the condition-based maintenance to perform well, there are a couple of things that have to be done:

- The sensors for the equipment must be obtained and then installed correctly.

- Parameters must then be set to the normal conditions of the equipment and this should be based off of typical reliable standards.

In the past, the expense was much higher in order to obtain the sensors and software and it was harder for smaller facilities to take advantage of the benefits. However, with technology being much more widespread, prices have become affordable to most any size of facility and everyone is able to reap the benefits of this technology.

Enhanced Condition-Based Maintenance

Here are a few of the most common variables a CMMS program can monitor when enhanced for condition-based maintenance:

- Equipment temperatures through infrared imaging

- Lubricant viscosity and wear metals through oil analysis

- Pressure states for fluid and airflow

- Cavitation and related wear damage

- Vibration frequencies for detecting structural looseness, misalignment, bearing issues, sheave run-out, and many electrical problems

Read More: Easy Tracking of Critical Temperature Changes

No matter what type of equipment your facility needs to monitor, condition-based maintenance is not only helpful to keeping up with much-needed data, but it is a technology that renders the facility more cutting-edge and on top of their game.