Data helps us make important decisions related to budgets, plans and even day-to-day priorities. In facilities maintenance, reports can tell you a great deal about the efficiency of your team, the lifespan of your equipment and where dollars are being spent.

Reporting can offer granular views of tasks and assets, as well as a big-picture outlook on the growth, profits and success of your organization.

Using a Computerized Maintenance Management System, or CMMS, allows facility managers to have constant awareness of the state of their operations through detailed reporting.

See reporting with a CMMS in action by booking a demo today!

There can be a lot to keep track of in terms of maintaining a healthy facility, and parsing all that data can become overwhelming. However, if you keep your overall goals and objectives top of mind and work backward to pull metrics that offer insights into your progress, your reporting will work better for you.

Traits of an Effective Maintenance Report

There are numerous reports you can run to offer a glimpse or detailed view into how well your facility is functioning. A maintenance report can include asset expenses, staff performance, facility trending, scheduled work orders and much more. Intuitively, you’ll know what data and information you want to monitor. But how do you know if your report is really providing the insights you need?

An effective maintenance report will be:

-

Accurate

-

Relevant

-

Straightforward

-

Timely

Accuracy is key in using data to make educated and informed decisions. Inaccurate information can have disastrous consequences, such as unforeseen equipment failure or safety hazards that could have been prevented. All reports you run should be factual and include enough data to give you a full, clear picture of what’s going on.

Reports should be relevant, meaning the data you’re collecting will actually be used to keep track of what’s necessary. Tracking unneeded information can be a time-suck and complicate your reports.

Speaking of complicate, good maintenance reports should be simple to access, peruse and comprehend. Quality maintenance reporting software will offer a quick, visually appealing and easy way to interpret your data and get a reliable overview of all your systems.

All reporting should be timely, meaning dates should be logged and information should be entered and updated frequently. Your data should reflect the present state of your facilities, tracking the date of equipment purchases to gauge when they will need upkeep or repairs, to when compliance-related checks or work order requests were completed.

Insights from Your Maintenance Reporting

Maintenance reports can be used to track KPIs or other performance-based activities. While important, in facilities maintenance, reporting may more commonly be used to keep track of what work was performed when and where resources need to be allocated in the future.

With the right CMMS in place, you’ll be able to customize your reports to get the exact information you need, when you need it. One moment you may need a clear picture of which tasks are pending, while later on you might need to send a report to leadership on how many tasks were completed last year.

Here are a few examples of common maintenance reports and the insights they offer:

-

Asset History: Logging the purchase date and details about all assets is key to understanding their longevity and safety, as well as what purchases need to be made and when. This can help with budgeting decisions and considerations now and in the future.

-

Staff Performance: Tracking which team members are completing work orders and other relevant tasks can give managers insight into promotions, bonuses and other employee rewards and incentives. It can also pinpoint areas for improvement among the team.

-

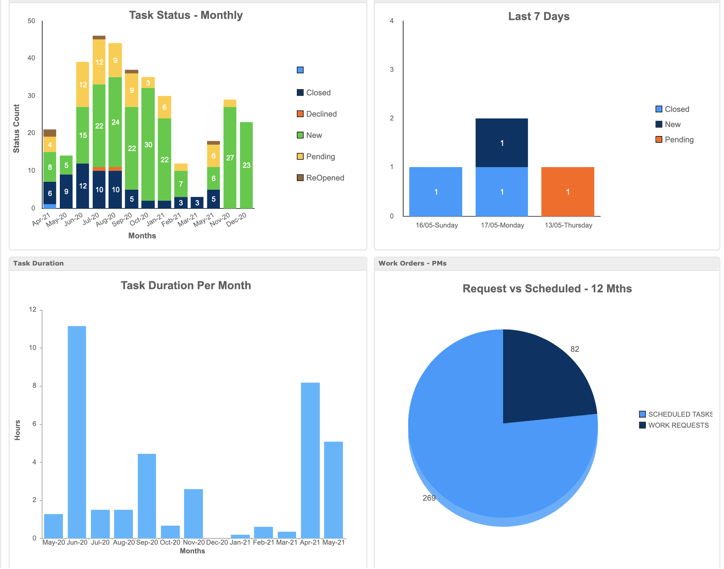

Task Duration: Logging how long a task takes to complete can help facilities managers prioritize requests and identify opportunities to expand the team or maximize efficiencies that can speed up slower projects.

What a Maintenance Report Looks Like

Going paperless with a CMMS offers additional flexibility in the appearance and layout of your maintenance reports. Data can be broken into pie charts and bar graphs to make it visually easier to digest.

No matter how you decide to customize your report, the document or dashboard should contain specific detail that allows the viewer to see the big picture, as well as drill down and dig deeper for more specific information.

Run a Maintenance Report the Simple Way

Tracking information and running reports can give you more control over your operations and better plan ahead for future repairs, costs, staffing and growth.

A CMMS with full reporting capabilities will allow you to design and export maintenance reports when and how you want to. Book a demo today to see how Maintenance Care can help.